Choose an environmentally friendly packaging printing coating solution to meet your business needs.

- Mega Uni-Trade Team

- Sep 1, 2025

- 10 min read

Updated: Sep 3, 2025

Environmentally friendly packaging coatings are coatings designed to enhance the appearance, durability, and protection of printed materials. The key is to use ingredients that are safe for consumers and easily biodegradable or recyclable, minimizing the impact on the planet.

Transforming the packaging industry to new standards

In the past, many packaging coatings were loaded with harsh chemicals or volatile organic compounds (VOCs), which were harmful to both health and the environment. However, today , environmentally friendly packaging coatings are becoming the new standard and are being used as a key strategy by businesses around the world.

Think of the coating as a "jacket" for your product box. Traditional armor may be strong, but when thrown away, it becomes a polluting waste. But this new armor not only provides excellent protection for your product, it is also designed to be biodegradable and easily recycled.

What is the real difference?

The main difference lies in the “ingredients” which directly affect the application and results. Eco-friendly coatings tend to use natural ingredients or are primarily water-based, which reduces the release of toxic substances in the manufacturing process and is safe for the end consumer.

This trend clearly aligns with the market's direction. Data from 2021 indicates that the Thai printing and packaging market is worth a whopping 140-150 billion baht and grew by around 5% year-on-year. A key driver is the exponential growth of e-commerce, which has driven demand for boxes and labels. As a result, most manufacturers are adapting to using environmentally friendly materials and coatings to gain a competitive advantage. Read more about packaging market trends in Thailand.

Choosing an eco-friendly coating isn't just about following a trend. It's about investing in your brand's future, demonstrating social responsibility, and building long-term customer trust.

Understanding these solutions is a crucial step for any business looking to grow sustainably, as the benefits range from building a credible brand image to unlocking new business opportunities.

Deep dive into popular environmentally friendly coatings

To help you choose the most suitable solution for your products and production lines, let's understand the features of each type of eco-friendly packaging coating.

Choosing the right type of box not only helps make the box look beautiful and durable, but also has a direct impact on production costs, work processes, and most importantly, the impact on the environment.

1. Water-based Coatings

This is the most popular option today for the simple reason that it uses water as the primary solvent instead of harsh chemicals, resulting in very low levels of volatile organic compounds (VOCs), making it safe for both printer workers and consumers.

Immediately applicable features:

Low odor: Suitable for packaging food and medicine that does not want to be contaminated with foreign smells.

Easy to clean: The device can be washed with plain water, reducing the use of chemicals and saving time cleaning the printer.

Highest safety: It is the number one choice for packaging mother and baby products or products that emphasize safety.

2. UV Coatings

For businesses that require fast production speed and outstanding results, UV Coatings are the answer. Their key feature is that they dry immediately upon exposure to ultraviolet (UV) light, enabling faster production and reducing bottlenecks in the manufacturing process.

Immediately applicable features:

High gloss: Creates a premium and luxurious feel to packaging such as cosmetic or electronic product boxes.

Extra durable: Excellent scratch and moisture protection, ideal for products that go through multiple transportation stages.

Improved productivity: Reduced drying time allows for faster delivery.

3. Bio-based Coatings

This is a truly sustainable innovation. Made from naturally renewable raw materials such as corn starch or polylactic acid (PLA), the coating is biodegradable.

Immediately applicable features:

Create an environmental selling point: This is ideal for brands that want to clearly communicate their concern for the planet, such as organic products or brands targeting green consumers.

Solves the challenge of disposable packaging: It is the perfect solution for takeaway food packaging that wants to reduce plastic waste.

Build the brand image of the future: Be the first to adopt this innovation to help your brand stand out and lead the market.

Choosing the right coating is the first step in creating packaging that's not just aesthetically pleasing, but also tells a story about caring for the environment, something that modern consumers truly value.

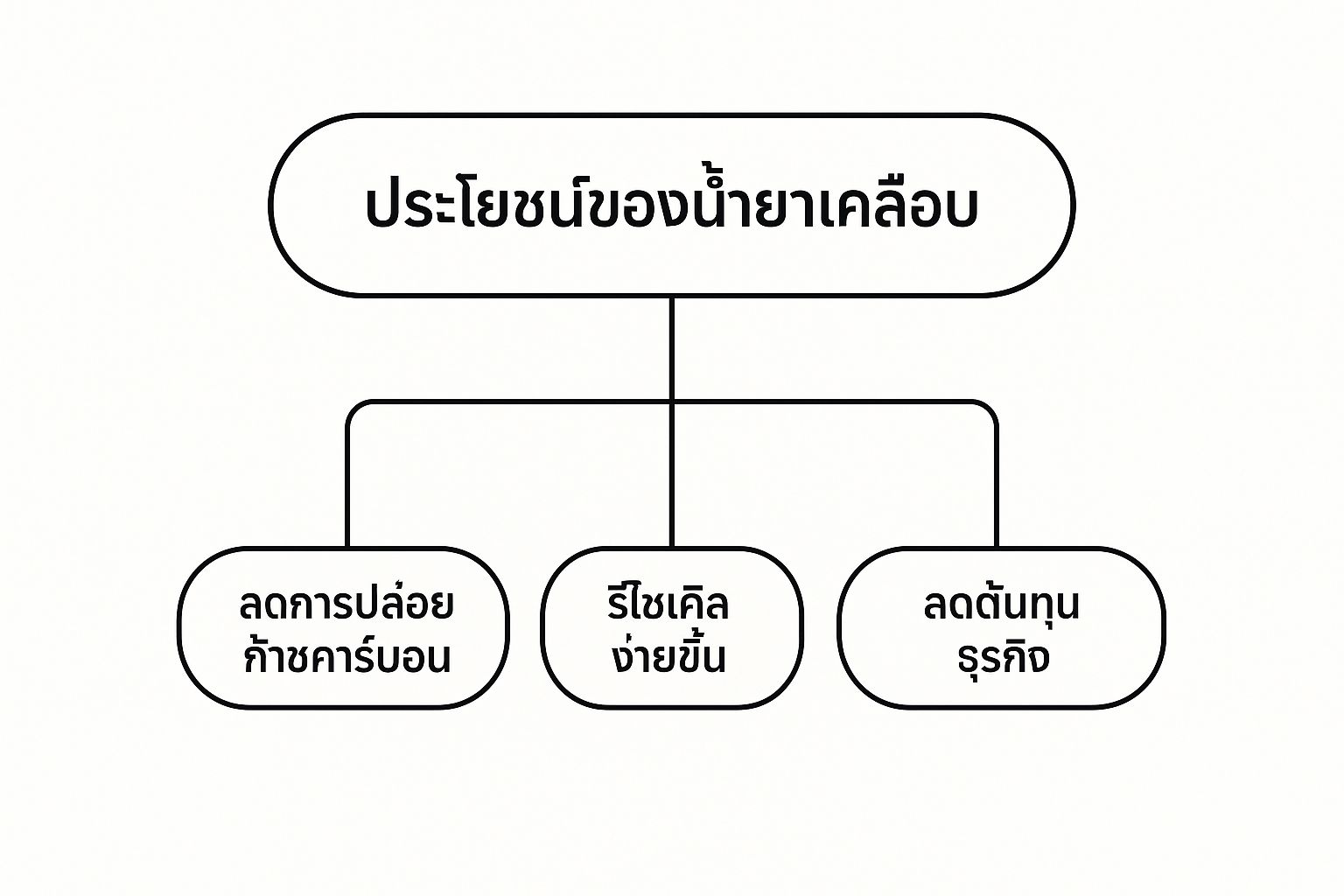

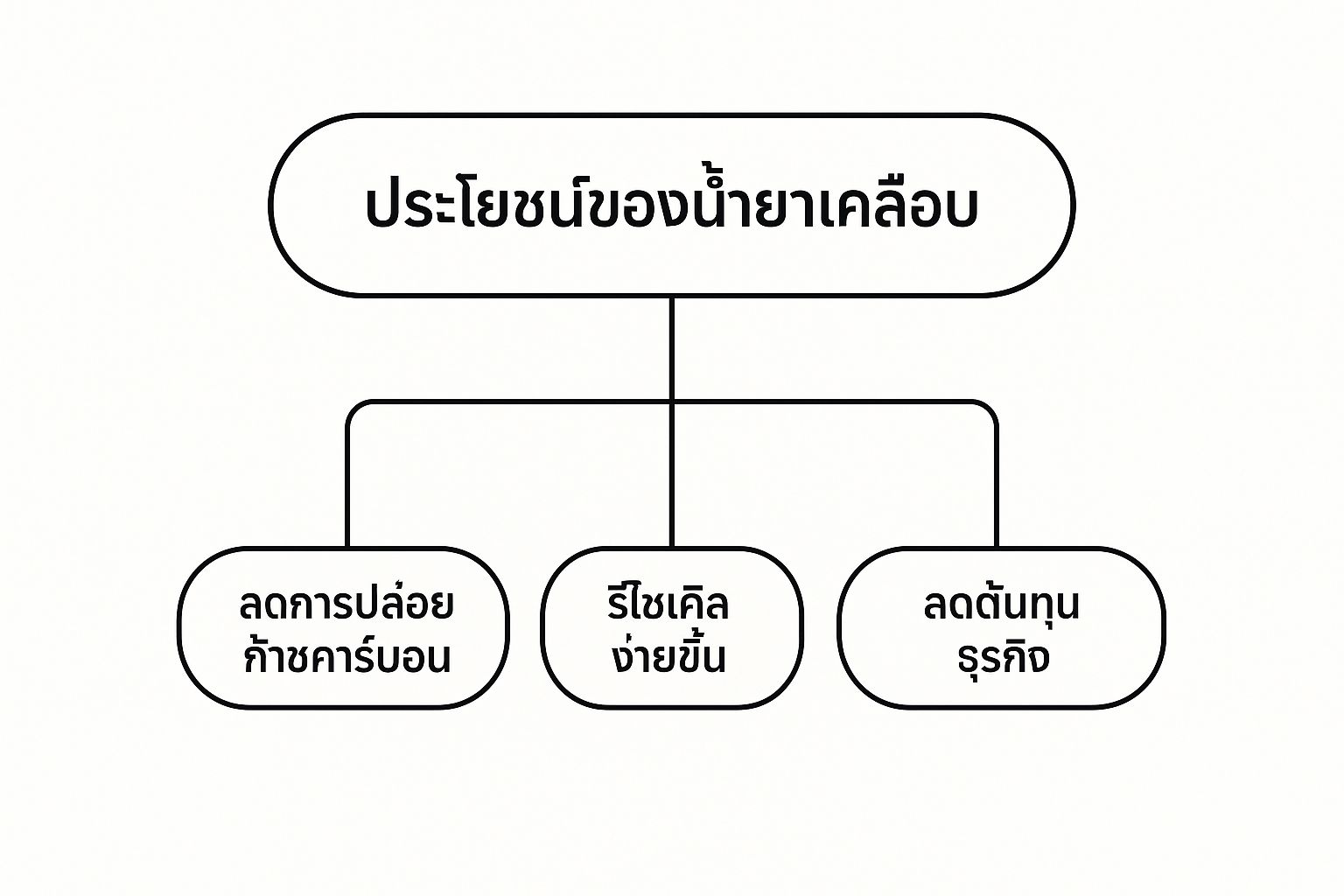

The image below clearly illustrates how switching to this kind of eco-friendly solution benefits everyone.

As you can see from the image, the benefits are all interconnected, from reducing environmental impact and making packaging easier to recycle, to creating long-term value for your business.

To give you a clearer picture, let's take a look at a comparison table of the properties of each type of coating. This table will help you summarize the advantages, limitations, and appropriate uses to make it easier for you to decide on the right solution for your business.

Compare the properties of different types of environmentally friendly coatings.

Type of coating | Outstanding features | Limitations | Suitable for packaging |

|---|---|---|---|

Water formula | High safety, low VOCs, odorless | Slower drying than UV, medium glossiness | Food, medicine, children's toys, general consumer goods |

UV | Very fast drying, high gloss, scratch resistant. | UV light equipment is required, it has a unique smell. | Cosmetics, electronic products, luxury packaging |

biological | Biodegradable, plant-based, highly environmentally friendly | Higher price, may be less durable than other types | Organic products, disposable food packaging |

Understanding these differences will help you choose an environmentally friendly packaging coating that best meets both your product and your brand's goals.

What will your business gain from this change?

Switching to environmentally friendly packaging coatings is not just about following a trend, but also a smart business decision that delivers tangible returns in multiple dimensions.

Simply put, it's like upgrading your brand to be more modern and ready for a future where sustainability becomes a key factor in consumer purchasing decisions.

This shift has a direct impact on today's increasingly environmentally conscious customers. Your packaging will become more than just a box, but a powerful communication tool that speaks volumes about your brand's responsibility without words.

Enhance your brand image to stand out and win the hearts of customers.

In a competitive market, differentiation is key. Choosing eco-friendly packaging can instantly make your brand stand out. It shows your customers that your business is not just about profit, but also about its impact on society and the environment.

This is where emotional attachment builds with consumers, especially Millennials and Gen Z, who are willing to pay more to support brands that share their values. Building loyalty within this group means stable and growing sales over the long term.

Actionable Tip: Incorporating eco-friendly materials into your social media marketing or printing a QR code on your box for customers to scan for more information can help build transparency and credibility.

Reduce legal risks and open up new markets

It's no secret that global environmental regulations are becoming increasingly stringent. Adapting today will make it easier for your business to meet international standards and reduce the risk of future fines or trade barriers.

Importantly, environmentally friendly packaging also serves as a gateway to export markets in many countries, particularly in Europe and North America, where it is highly valued. This presents an opportunity to expand your customer base and grow your business globally.

Build credibility in the eyes of investors

Sustainable business practices are not only attractive to customers, but also to investors. Investors are now looking for businesses with a clear environmental, social and governance (ESG) approach, believing it to be an indicator of their ability to grow sustainably.

Choosing an environmentally friendly packaging coating is a tangible demonstration of corporate social responsibility (CSR), which can increase credibility and make your business more attractive to investors. Therefore, a change in your packaging can lead to greater business opportunities than you might think.

Market trends and the future of eco-friendly packaging

The world of packaging is changing dramatically, and the future is clear: choosing environmentally friendly packaging coatings is no longer an option, but is becoming a standard for businesses seeking sustainable growth.

There's an interesting backstory to this trend, including changing consumer behavior and government policies that are increasingly focused on the green economy. Understanding the big picture will allow your business to spot opportunities and prepare faster than your competitors.

Consumer Behavior: The Real Thing That Drives the Market

Today's customers are not only looking at product quality but also considering packaging. They are looking for brands that are 'honest' about the environment. Beautiful packaging that creates a lot of waste is increasingly being rejected.

Actionable Insight: "Sustainability" has become one of the key purchasing decisions. Brand transparency in material selection and post-use management is just as important as product quality.

The exponential growth of e-commerce is another key catalyst. Consumers experience the packaging directly, and simply using boxes made from recycled materials or coated with biodegradable materials can make a great first impression and turn new customers into loyal fans.

Government policies and global trends

Beyond consumers, government pressure and global trends are also key factors that cannot be overlooked. Many countries are introducing legislation to control single-use plastics and supporting businesses that follow the circular economy approach.

Recent figures reinforce this picture, with projections that between 2025 and 2027, the Thai packaging industry will grow at an average annual rate of 5.3% and could reach a market value of 572 billion baht by 2025. Much of this growth is driven by e-commerce businesses seeking lightweight, environmentally friendly packaging, which in turn has led to a corresponding increase in demand for environmentally friendly packaging coatings. Read more about the outlook for the packaging industry here.

Future innovations to watch out for

The future of green packaging doesn't stop at recycling, but is moving forward with exciting new technologies, more of which we'll be seeing soon.

Smart Coatings: Coatings that change color when food is nearing spoilage or help extend the shelf life of fruits and vegetables.

AI-powered design: Artificial intelligence will help design packaging that uses the least amount of material while maintaining strength (Material Reduction).

Advanced biomaterials: Materials from algae or fungi that are completely biodegradable in a short time.

Staying current on these trends and adapting is key to not only surviving, but also becoming a leader in the future of packaging.

Time for some real action: How to choose and use a coating that works

Once you understand the theory and market trends, it's time to put it into practice. Choosing an environmentally friendly packaging coating isn't complicated, but it does require careful planning to achieve results that meet your brand's quality, cost, and goals.

The first step is to clearly analyze your product's requirements. What is your product? What kind of special protection does it need? (e.g. moisture resistance, scratch resistance, or food contact grade) The answers to these questions are the most important starting point.

Next, consider your existing manufacturing processes and printers. Some coatings, such as UV coatings, may require additional equipment investment, while most water-based coatings are compatible with existing machinery. Understanding these limitations can help you eliminate unsuitable options.

Steps to choosing the right coating

To ensure you get the best results, try these simple steps.

Define the required properties (Checklist): List essential properties such as gloss-matte level, abrasion resistance, or 100% biodegradability to use as criteria for selection.

Consult an expert: Talk to a trusted supplier. They have in-depth knowledge and can provide advice that fits your business and budget.

Request a sample: It is best to test a sample of the coating on your actual material and print to evaluate both aesthetic and durability results before committing to a large-scale production order.

Switching to eco-friendly packaging is no longer just an option. It's a direction the entire industry must adapt to, in line with national policies, to ensure business growth and sustainability.

This direction is in line with the Thai government's policy targeting net-zero greenhouse gas emissions by 2065, forcing the packaging industry to accelerate the development and adoption of more environmentally friendly packaging coatings, particularly water-based coatings and bioplastics, to reduce environmental impact and meet the trend of lightweight packaging that also saves on transportation costs. Read more about the direction of the sustainable packaging market at Manufacturing Expo.

Frequently Asked Questions (FAQ) about Eco-Friendly Packaging Coatings

Here are some frequently asked questions from entrepreneurs considering switching to environmentally friendly packaging coatings, to help you make a more confident decision.

Is it true that eco-friendly coatings are more expensive than traditional ones?

The answer is that initially, the unit cost may be slightly higher, especially for bio-coating solutions. However, in the long term , it is more cost-effective.

The reason is:

Reduce hidden costs: Water-based coatings reduce the steps and costs of cleaning that require harsh chemicals.

Add value to your product: Eco-friendly packaging creates a premium image and attracts customers who are willing to spend more.

Increase sales: Addressing the needs of green customers can expand the customer base and increase sales to offset additional costs.

Actionable Tip: Don't just look at unit price, but also assess the total cost of ownership (TCO) and the return on sustainable branding.

Do I need to replace the machine or completely change the printing process?

The good news is, there's no need to invest in a complete new machine. Water-based coatings are designed to work with most existing printers right out of the box, but minor adjustments, such as temperature or curing speed, may be required to achieve the best results.

For UV Coatings, additional investment in UV lamps may be required, a one-time investment that can significantly increase production speed. It is best to consult with your supplier to find the right solution for your production line.

How can I be sure that the coating I choose is up to standard and safe?

The easiest and most reliable way is to check the supplier's international standard certificate, which is a guarantee of quality and safety.

ISO 9001: Certification of Quality Management Systems for Manufacturing Processes

Food Grade Certification: Essential for packaging that comes into direct contact with food.

Safety Data Sheet (SDS): Request this document to review all ingredients and safety information.

Choosing a partner with expertise and full certification will ensure that your chosen eco-friendly packaging coating is safe for consumers and meets world-class standards.

Is the coated packaging 100% recyclable?

In general, paperboard packaging coated with water-based or bio-based coatings is easier to recycle than traditional coatings because the coating does not interfere with the pulping process.

However, 100% recyclability depends on other factors such as the type of paper, the thickness of the coating and the technology of the recycling plant in each area.

Actionable Tip: Communicate directly with customers by including clear recycling symbols and sorting instructions on packaging to encourage proper recycling.

Choosing the right printing materials is key to creating beautiful and sustainable packaging. At Mega Uni-Trade, we have over 35 years of experience in selecting and distributing high-quality water-based and UV coatings, along with a full range of premium printing consumables. Consult our experts to find the right solution for your business at https://www.megaunitrade.com.

This article is provided for educational purposes only and is offered ‘as is.’ Mega Uni-Trade Co., Ltd. accepts no responsibility for any losses or damages resulting from its use.

%20copy.png)

Comments